Biogas Desulfurization and Biogas Upgrading Using a Hybrid Membrane System

Membrane gas permeation using glassy membranes proved to be a suitable method for the biogas upgrading and natural gas substitute production on the account of low energy consumption and high compactness. Glassy membranes are very effective in the separation of bulk carbon dioxide and water from a methane-containing stream. However, the content of hydrogen sulfide can be lowered only partially.

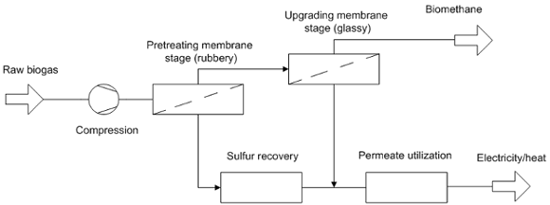

A simplified process scheme including process integration of the hybrid membrane system for the desulfurization and upgrading of biogas

This work evaluates a hybrid membrane system built of a combination of rubbery and glassy membranes. The former are responsible for the separation of hydrogen sulfide and the latter separate carbon dioxide to produce standard-conform natural gas substitute. The evaluation focuses on the most critical upgrading parameters like achievable gas purity, methane recovery and specific energy consumption. The obtained results indicate that the evaluated hybrid membrane configuration is a potentially efficient system for the biogas processing tasks that do not require high methane recoveries but allows effective desulfurization for medium and high hydrogen sulfide concentrations without additional process steps.

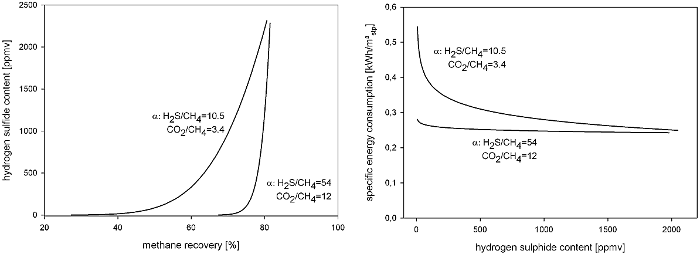

Stage-cut variation of the first stage of the hybrid membrane configuration, left: hydrogen sulfide content after first stage versus methane recovery of the whole system, right: specific energy consumption versus hydrogen sulfide content after first stage, hydrogen sulfide content in raw gas is equal to 2500 ppmv.