Chemical-oxidative scrubbing for the removal of hydrogen sulphide from raw biogas: potentials and economics

In the present work chemical-oxidative scrubbing as a novel method for the desulphurisation of raw biogas is presented with a special focus on the process potentials and economics. The selective absorption of hydrogen sulphide from gas streams containing high amounts of carbon dioxide using caustic solutions is not trivial but has been treated in literature. However, the application of this method to biogas desulphurisation has not been established so far. Based on rigorous experimental work, an industrial-scale pilot plant has been designed, erected and commissioned at a biogas plant with biogas upgrading and gas grid injection in Austria.

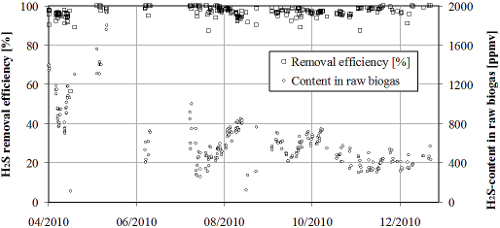

H2S-content of the raw biogas and H2S-removal efficiency of the chemical-oxidative scrubbing process. Data collected from the pilot plant Bruck/Leitha between April and December 2010.

Data collected from the 12-month monitored operation has been used to elaborate performance as well as economic parameters for the novel desulphurisation method. The proposed technology offers significant operational advantages regarding the degree of automation and the flexibility towards fluctuations in process boundary conditions. Furthermore, the economic assessment revealed the high competitiveness of the chemical-oxidative scrubbing process compared to other desulphurisation technologies with the named advantageous operational behaviour.

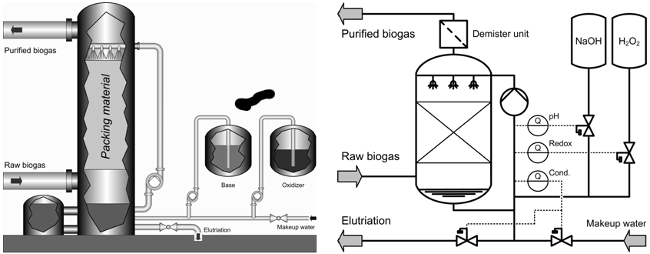

Process scheme (left) and process flowsheet (right) of the chemical-oxidative scrubbing pilot plant Bruck/Leitha