FE und CFD-Simulations for Design-Optimization and Up-Scale of Fibre-Drawing-Tools for the Production of endless Filaments of Volcanic Rock Melts

With a project partner from industry novel fibre-drawing-tools for endless, amorphous fibres of high-temperature mineral melts have been developed.

Motivation for the CFD/FE-Simulations:

- Experimental research of complex flow behaviour inside the fibre-drawing-tool

- Calibration of the models on the current design in a production facility

- Extension of life expectancy of the current design

- Reduction of mechanical stresses in the noble metal of the fibre-drawing-tool

- Solutions for new and innovative designs

- Model development and parallel process-integration

- Simulation and creation of design proposals for the scale-up to high tip numbers

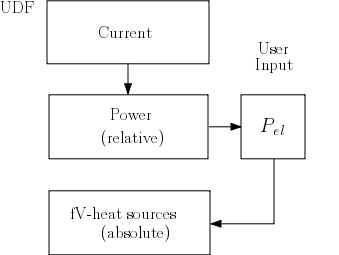

The CFD-simulations were based on the model for direct electrical heating developed as early as 2006 and 2007 in the work group „Thermal process engineering and simulation”. This model allows simulations of current densities in arbitrary, directly contacted, electrically conducting work pieces. The following figures explain very shortly the schematics of the UDF (User Defined Function) which was implemented in Ansys Fluent 6.

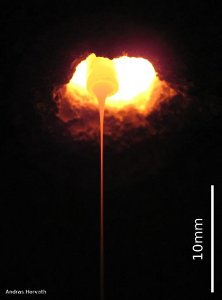

Figure 1 und 2: Left: Schematics of the UDF in Fluent for the simulation of the directly heatet fibre-drawing-tool. / Right: Detail of a drawing experiment at the monofilament unit in the technical room of the Institute of Chemical Enginnering. Surface-temperature: 1350°C. Core-temperature : 1400°C. Winder-speed : 20 m/s.